Product Sector: Vegetables, Salad and Fresh Cut

A leading Salads producer supplying coleslaw to the own brand supermarket chains had a major cleaning issue with the elevating equipment previously used. The elevators received sliced/diced carrot, cabbage and onion and elevated to a high level but were fully enclosed and difficult to clean.

The Challenge:

The existing elevator systems comprised of a tubular screw conveyor mounted on a swivel base and fitted with an elaborate system of pneumatic cylinders to allow the conveyor to be swivelled away from the mixer for cleaning. The auger which was 4m in length had to be withdrawn from the casing before cleaning could commence.

The considerable manual handling and risk involved whilst removing and re assembling the auger caused health and safety issues for the operatives.

Insights:

Dodman has a great deal of experience offering specialist equipment for demanding applications within the food industry. The Dodman design team worked closely with our customer to resolve the manual handling and cleaning issues, producing a hit list of priorities to be addressed. This collaborative effort ensured the design team were fully focused on the key issues that would ensure practical solutions and maximum benefit.

Our Solution:

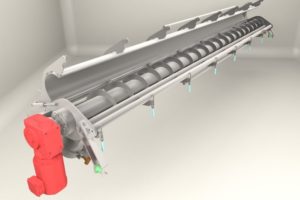

The collaborative design team prepared a unique design that allows total access to the scroll and inner casing without the removal of the auger. This innovative design is achieved by hinging the auger casing whilst in situ. Gas springs were used to assist the opening of the casing with minimum manual effort. An innovative locking mechanism uses an easily operated over-centre cam system (all interlocked for safety purposes). This brings about the total accessibility of the auger for hygiene staff without the need to reposition the elevator

Result: The Dodman Easi Clean Auger

The new Auger design reduced down-time for cleaning and hygienic assessment whilst reducing manual handling. The Dodman Easi Clean Auger is simple to use, exceedingly easy to clean and avoids component disassembly ensuring full access for cleaning and inspection with a high level of safety.

Dodman have more than 30 years of experience supplying food processing and handling systems to the food industry. If you are interested to know more about Dodman, this specific project or have similar challenges to overcome, please give us a call, we would very happy to help you develop your processes.